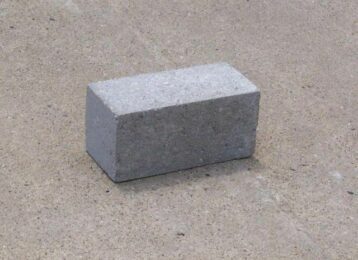

A concrete block is a ‘building block’ built entirely of concrete, which is subsequently joined with mortar to create a commanding, long-lasting construction. Depending on the exact demand, these construction blocks may be ‘hollow’ or ‘solid’ and made of heavy-duty or lightweight concrete in various conventional sizes.

These concrete blocks can be utilised as a masonry component for panel walls, partitions, and load-bearing walls. They are employed where it is difficult to get brick or stones of the right quality and strength needed for masonry, but it is much easier to find the appropriate aggregates.

Source: Pinterest

Concrete blocks: Types

These concrete blocks can be divided into:

- Blocks of solid concrete,

- Blocks of hollow concrete

Blocks of solid concrete

A block is classified as a solid concrete block if concrete makes up more than 75% of its entire mass in relation to its overall dimensions. It also goes by the name concrete brick.

Blocks of hollow concrete

A hollow concrete block only contains solid material in 50–70% of the entire volume, as determined by the overall dimensions. Hollow concrete blocks may include one or more sizable “holes” or “cavities” that may pass through the block (open cavity) or may only be there (closed cavity) to lower the bulk without sacrificing strength.

Hollow concrete blocks are further divided into Grade A and Grade B categories. Since cinder is the aggregate most frequently used as the material basis, this Grade B category is occasionally called “cinder block.”

The shapes and sizes of hollow concrete blocks on the market vary widely. These are frequently used according to their placement or position on the wall. They include concrete stretcher blocks, concrete lintels, concrete partition blocks, concrete pillar blocks, concrete corner blocks, concrete jamb blocks, concrete bullnose blocks, and frogged brick blocks, among others.

For the following reasons, hollow concrete blocks are utilised more commonly than solid ones:

- They are lighter overall, making them easier to handle.

- They may readily fulfil complex structural requirements despite being groutable and strengthened.

- Because of their additional heft, solid concrete blocks are rarely used in day-to-day construction. It calls for certain demands, needs, and standards, such as higher fire resistance, sound absorption requirements, or a necessity for impenetrability.

Source: Pinterest

Concrete blocks: Benefits

- The benefits of using concrete blocks include making a room appear larger by expanding the carpet area owing to the concrete blocks’ decreased thickness compared to a traditional brick masonry wall.

- Improved thermal insulation is offered.

- Protects rooms from noise pollution since it better absorbs sound

- Adds additional fire protection

- Protects priceless agricultural land that would have otherwise undergone significant excavation to produce clay bricks.

- Due to the massive size of the blocks, concrete block construction is more organised, quicker, and stronger than brick masonry.

- The ability to create individual components in bigger bespoke sizes and shapes ensures a rapid production cycle. Compared to traditional brick construction, fewer joints result in a lower mortar consumption rate while increasing the building’s overall strength.

- Contrary to ordinary bricks, concrete blocks are homogeneous in size, reducing the need for plaster and making them economically feasible.

Concrete blocks: Applications

Concrete blocks for wall construction

Concrete blocks are highly advantageous for partition walls since they allow rapid and simple installation. It gives the structure more strength with the addition of steel reinforcement.

Solid concrete blocks are excellent for building fireplaces and chimneys but also work well for garden and non-load-bearing walls.

Hollow concrete blocks are frequently utilised for exterior and interior load-bearing walls, partition walls, panel walls, boundary walls, etc.

Blocks of concrete used to create a material bin

The items kept can be shielded from various environmental conditions by concrete blocks. It makes sense that engineers continue to use it to construct material bins. Construction businesses choose to use this precisely because it keeps the materials apart—these concrete Blocks store materials like rock, aggregate, etc., for a long time.

Landscaping projects using concrete blocks

Several little landscape projects also employ concrete blocks, for instance, in many designs for outdoor seating, decorative screens, outdoor bars, flower beds, and patio furniture.

Source: Pinterest

Concrete blocks: Manufacturing process

The following fundamental steps comprise the manufacturing process:

Proportioning

According to the Indian Standard Code 2185 – Part 1 or in accordance with the required strength, the material percentage is taken.

Combining

Precise batching of the components and thorough mixing are required to obtain a uniform mix. The process must continue until the components are distributed evenly.

Compacting

Vibro compaction should be used to compact the block and finish to the right size without any broken edges.

Treatment

The blocks must be kept consistently wet for at least 14 days while curing in a water tank or yard. The water in the immersion tank where the blocks are curing should be changed at least every four days.

Drying

The blocks must dry for two to three weeks after curing before being suitable for usage in various ways. Walls can develop shrinkage cracks if you don’t follow its instructions.

FAQs

What are concrete blocks made of?

Concrete blocks are made of a mixture of Portland cement, water, and aggregates such as sand, gravel, or crushed stone.

What are the different types of concrete blocks?

There are several types of concrete blocks, including standard, lightweight, and dense concrete blocks. Other types include interlocking, hollow, and solid concrete blocks.

What are concrete blocks used for?

Concrete blocks are commonly used to build walls, foundations, and retaining walls. They also create landscaping features such as garden walls and steps.

What is the standard size of a concrete block?

The standard size of a concrete block is 8 inches by 8 inches by 16 inches.

| Got any questions or point of view on our article? We would love to hear from you.

Write to our Editor-in-Chief Jhumur Ghosh at [email protected] |

Housing News Desk is the news desk of leading online real estate portal, Housing.com. Housing News Desk focuses on a variety of topics such as real estate laws, taxes, current news, property trends, home loans, rentals, décor, green homes, home improvement, etc. The main objective of the news desk, is to cover the real estate sector from the perspective of providing information that is useful to the end-user.

Facebook: https://www.facebook.com/housing.com/

Twitter: https://twitter.com/Housing

Email: [email protected]