The need for technological advancements in the concrete sector is rising due to growing construction costs and a lack of available workers with the necessary skills. Although concrete technology has been around for a while, it has recently gained favour to lessen the need for human labour and cut overall construction expenses, owing to evolving technologies and patterns.

The definition of concrete technology and the most recent developments in the industry will both be covered in this article.

Concrete technology: What is it?

Concrete is an essential material for constructing buildings because it can be used to create strong composite materials like foundations, slabs, and other load-bearing parts. Concrete technology involves studying the characteristics of concrete and gaining hands-on experience, followed by its application in the real world.

See also: Types of building materials

Concrete technology: New trends in concrete technology

The following are some of the latest developments in concrete technology that are helping to cut down on the expenses of construction while simultaneously increasing productivity both on and off the work site.

-

UHPC

Source: Pinterest

Ultra-High Performance Concrete is a more recent development in the field of concrete technology. Although it does include fibres, UHPC still comprises standard concrete for the most part (around 80%). These fibres, which may vary in durability from polyester to steel material, provide the final product resilience and strength.

In addition, UHPC may last for up to 75 years, while regular concrete typically only lasts for 15-25. From 2019 to 2024, the worldwide UHPC market is projected to expand from 2019’s USD 369 million to 2024’s USD 550 million, representing a CAGR of 8.3 per cent.

-

Self-healing concrete

Source: Pinterest

It is inevitable that concrete will deteriorate, leak, and flex after it has been poured. Self-healing concrete includes microorganisms that produce limestone and fix cracks when exposed to air and water. This self-healing bacteria may be used to fix mortar in preexisting buildings as well as concrete. When fractures are between 0.05 and 0.1mm in width, they may be permanently sealed by cycling between dry and wet conditions repeatedly. Like a capillary, the self-healing substance draws water through the fissures. Subsequently, the cement is hydrated and expands as a result of the water particles, sealing the crack. However, more reconstructing work will be necessary if cracks are wider than around 0.1 mm. There are two approaches to making self-healing concrete:

known about micro concrete

-

By means of direct application

Add calcium and microbial spores to the concrete after it has been mixed. Self-healing concrete is produced when water meets these microorganisms, which then germinates on calcium lactate and produces limestone via the closure of fissures.

-

Through encasement in lightweight concrete

The pellets of clay contain the microorganisms and calcium lactate, which are incorporated into the concrete. About six per cent clay pellets are used in the self-healing concrete mix. Clay pellets disintegrate when a hole opens up, allowing bacteria to proliferate and live on the calcium lactate, ultimately resulting in the formation of limestone.

-

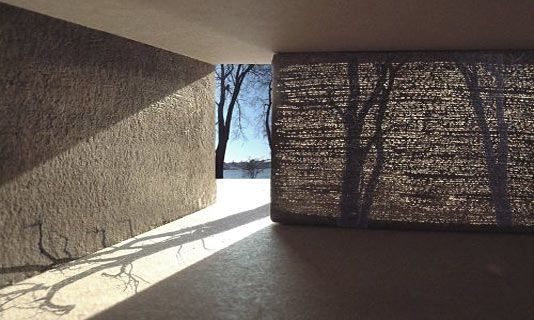

Graphic Concrete

Source: Pinterest

Graphic concrete provides architects with the ability to create unique, fascinating, and memorable images of precast concrete surfaces. With the use of graphic concrete technology, an image may be generated on a membrane and then transferred to a slab of precast concrete. The membrane may be formed into any desired form as well as disposable.

Modern concrete technologies now let you create uniquely patterned floors and walls. You can make graphic concrete your own by choosing the pigments and shades you want to use in your creations.

Compared to other prefabricated concrete surfaces, graphic concrete is more cost-effective. They are completed and ready for use, so extra coatings or surface treatments are not required. In general, graphic concrete may shorten the duration of a building’s construction and lower its overall cost.

-

Light-generating concrete

This new approach in concrete technology was pioneered by Jose Carlos Rubio Avalos. Light is both absorbed by and emitted by this concrete. Since this concrete can be made at ambient temperature, it requires substantially less energy to produce. Concrete can store solar energy throughout the day and release it as a light for around 12 hours. You may now be wondering how on earth this concrete can harness the sun’s rays. Since the cement lacks the crystallisation supplement, light may penetrate it and appear inside.

Roads, bridges, bike routes, and more may all benefit from this sort of concrete since it does not need electricity. The production method releases just water vapour as waste gas, making this a more sustainable option. The average lifetime of concrete with built-in lighting is around 100 years. Roads and bridges may be illuminated by the green or blue light emitted by a variety of concrete materials. Changing the illumination during manufacturing may help make streets and sidewalks safer for vehicles, bikers, and pedestrians.

-

Translucent cement

Source: Pinterest

Cement and other translucent concrete materials are being used to recreate iconic building styles. Fibre optics are the core of this cutting-edge technology, which comprises many layers of shielding and concrete. Light can go both ways via these fibres.

The structural and aesthetic needs of a given project may be met by tailoring the use of translucent concrete. It is possible to gauge the degree of see-throughness of the concrete by controlling the fibre diameter and saturation. Translucent cement is favoured by architects and designers over conventional concrete for the purpose of embellishing functional elements like staircases and dividing walls.

-

Drones

Source: Pinterest

The use of drones is among the newest developments in concrete technology, and its popularity on building sites is only expected to grow. Drones are mostly used for airborne surveying and inspection, providing information that the contractor lacks.

Companies in the construction industry have profited greatly from the usage of drones, despite initial reluctance to embrace the technology. Drones are helpful for concrete experts since digital optimisation of designs is made easier with their assistance. Drones guarantee on-time completion of projects by providing a bird’s-eye view of the site that helps discover any issues early.

-

3D Printing

Source: Pinterest

A wide variety of materials, not simply plastic and metal, may be used in a 3D printer. Recent advances in 3D printing technology have opened the door to the prospect of rapidly constructing low-cost neighbourhoods. When compared to conventional building methods, 3D concrete printing has several advantages, including the ability to make structures at lower cost and in less time, as well as the ability to manage greater dimensional analytics.

Due to the fact that this is a relatively recent development in the field of concrete technology, it is seldom employed for massive construction endeavours. The reason being this method works best with moderately big buildings, relatively inexpensive constructions, and short construction times. In comparison to conventional building methods, 3D concrete printing results in much less waste.

-

Off-site construction

Source: Pinterest

The term “off-site construction” refers to the practice of designing, fabricating, and assembling parts away from the final installation site. Off-site concrete processes typically consist of using prefabricated or precast concrete. Off-site construction is preferable due to the scarcity of experienced workers since it is more productive, safer, less expensive, faster, and of more uniform quality.

Because of its high adhesiveness, Ultra-High Performance Concrete (UHPC) may be used in prefabricated bridge components and systems. By using this method, the beams and deck of a bridge may be constructed at a separate place before being transported to the construction site for assembly.

-

Project Management Software

Concrete contractors might benefit from the use of specialised construction management software. Concrete and masonry workers provide the groundwork for commercial building projects. They provide comprehensive services, from initial site preparation to the last touches, with a focus on timely completion and high quality. If the project is managed using the standard procedures, it may be significantly delayed, which would incur extra costs and waste valuable time. Project management software is useful for keeping tabs on the progress of a concrete building in real time.

-

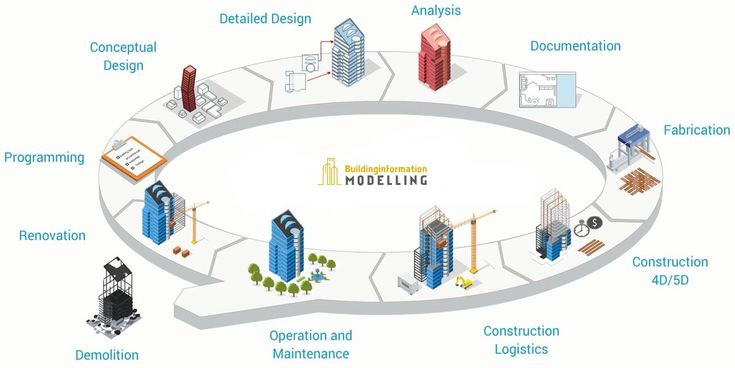

BIM

Source: Pinterest

The concept of Building Information Modelling (BIM) has been around for decades, yet technology is constantly evolving. The software’s 3D modelling capabilities provide designers with a comprehensive view of a project from every angle before it is built. By using BIM, the extent of the concrete development can be conveyed to all involved stakeholders. Because of improved coordination with the field crew and visibility of the formwork in its as-built state, the whole construction process runs more smoothly. Overall, BIM may help the supply chain run more smoothly by cutting down on inefficiencies like waste, delay, and error.

-

Artificial Intelligence (IoT)

Predictive maintenance and boosted production cycles are both possible with the help of IoT sensors and GPS trackers installed on concrete building equipment. One of the more recent innovations in the concrete building industry is the use of “intelligent equipment,” which is able to harness human expertise using computational methods. When sensors are installed on machinery, they provide field personnel with real-time data on the status of such assets, eliminating the need for guesswork.

Cement can’t fully form until the curing and strengthening processes have run their course. In order to maintain the necessary chemical reactions inside the concrete, IoT applications may automatically manage temperatures and humidity. Even while spending money on cutting-edge technology might hurt your wallet, it’s worth it in the long run since it solves issues and helps you plan for the future. Artificial intelligence and IoT data give concrete contractors the ability to keep tabs on their projects, get the information they need fast, and make choices in a timely way.

FAQs

What use does concrete technology serve?

Understanding the characteristics of concrete and gaining hands-on experience is fundamental to the field of concrete technology, which focuses on putting that knowledge to use in the built environment.

Why is concrete technology so important?

It covers the qualities of concrete required in building applications, such as performance and toughness, and makes recommendations on all elements of concrete, from design mix through batching, mixing, shipping, placing, solidifying, and curing.

What's the latest in concrete technology?

UHPC is a unique concrete technology that incorporates a number of non-traditional constituents, such as fibres, while retaining around 80% of the components of conventional concrete. Polyester and stainless steel fibres both contribute significantly to the product's strength and longevity.

What does sustainable concrete mean?

A sustainable concrete building is one that is built to have little social effect over the course of its full life. When designing a building, it's important to consider both its immediate and distant effects when thinking about sustainability.

Housing News Desk is the news desk of leading online real estate portal, Housing.com. Housing News Desk focuses on a variety of topics such as real estate laws, taxes, current news, property trends, home loans, rentals, décor, green homes, home improvement, etc. The main objective of the news desk, is to cover the real estate sector from the perspective of providing information that is useful to the end-user.

Facebook: https://www.facebook.com/housing.com/

Twitter: https://twitter.com/Housing

Email: [email protected]