An expansion joint in building construction is a mid-structure separation aimed to reduce stress on building materials brought on by building movement. The main factors that cause movement in buildings at expansion joints include:

- Temperature changes that cause thermal expansion and contraction

- Sway brought on by wind

- Seismic activity

- Static load bending

- Live load bending

Source: Pinterest

Expansion joint: Functions

A piping system has expansion joints installed to absorb shock and vibration. They also have benefits like noise reduction and misalignment compensation. For thermal expansion in hot applications, special expansion joints can also be created. Standard materials for expansion joints include metal, rubber, and braid. Expansion joints are not braided stainless steel tubing with flexible or metal liners. The majority of applications where thermal expansion is a concern use metal expansion joints. The metal expansion joint disperses to account for movement and relieve pressure on the pipe as pipe temperature rises. Metallic bellows can be made out of a wide range of materials, including nickel alloys and stainless steel.

Expansion joint: Determining factors for expansion joints

The choice of expansion joints in the building is influenced by the following factors.

- Temp. in the area

- Humidity

- Weather conditions

- Building elevation and plan (dimensions)

- Construction irregularities

- Unrelated subjects

Expansion joint: Types

-

Construction joints

When the construction of concrete elements ceases for any reason, such as because the day is coming to an end, construction joints are the only kind of concrete joints that are provided in the building.

-

Contraction joints

Contraction joints are the only kind of concrete joints that are included in buildings to prevent shrinkage movement. If the structure does not have contraction joints, the shrinkage of the concrete components develops tensile stress, which aids in the cracking of the members.

There are three different types of contraction joints:

-

Complete contraction joint

Before casting the new section on top of the existing section in this type of joint, the bond between the existing and previous layers of concrete can be broken with the aid of bituminous or waterproof paper on the face of the elements.

-

Partial contraction joint

Although a contraction joint may occasionally separate the concrete, for stability reasons, reinforcement was supplied across the joint, which in part restrained the movement of the structural elements. It is known as a partial contraction joint for this reason.

-

Dummy joint

The concrete groove in either or both of the concrete’s surfaces is used in this type of contraction joint. Whenever the cement section is thin, this style of contraction joint is employed.

-

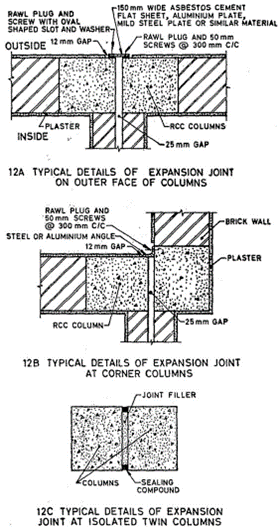

Sliding joints

When changes in temperature, moisture, or loading cause one part of a structure to move in a plane perpendicular to the plane of another part, sliding joints are provided in the concrete.

Expansion joint: The need for it in the building

In order to accommodate structural elements moving as a result of changes in temperature, moisture, and other factors, concrete is designed with expansion joints. It permits thermally-induced expansion or contraction of concrete structures without putting them under stress, which can lessen building cracking.

Expansion joints divide a long concrete structure into several sections, preventing earthquake vibration from spreading to other building components. Due to expansion joints, the long structure behaves as two or more separate structures in the event of an earthquake.

Source: Pinterest

Expansion joint: When should it be used in construction?

When a building’s length is longer than 45 metres, concrete expansion joints must be used, possibly more than one. Where a slab meets a building, another slab or a pool deck meets the coping, expansion joints are installed.

The position of expansion joints in a building is also impacted by the irregularities of the structure, including its mass, plan, stiffness, etc.

FAQs

How far apart must an expansion joint be?

Structures longer than 45 metres must be designed by one or more expansion joints, according to IS-456:2000. It is specified as 30 m in IS 3414, which is a code specifically for joints.

Where do expansion joints need to be used?

Before the concrete is poured, expansion joints are installed. Expansion joints are used to prevent the slab from stressing anything it abuts by allowing the slab to move. These joints are situated at the intersections of slabs that meet buildings, other slabs, and pool decks and coping.

| Got any questions or point of view on our article? We would love to hear from you. Write to our Editor-in-Chief Jhumur Ghosh at [email protected] |

Housing News Desk is the news desk of leading online real estate portal, Housing.com. Housing News Desk focuses on a variety of topics such as real estate laws, taxes, current news, property trends, home loans, rentals, décor, green homes, home improvement, etc. The main objective of the news desk, is to cover the real estate sector from the perspective of providing information that is useful to the end-user.

Facebook: https://www.facebook.com/housing.com/

Twitter: https://twitter.com/Housing

Email: [email protected]