A one-way slab is supported by two parallel walls or beams with a length-to-breadth ratio of two or greater bends only in one direction (the spanning direction) as it transfers loads to the two parallel walls or beams supporting each other. It spans and bends only in one direction.

See also: Slab designs: Types and uses

What is a one-way slab?

A one-way slab essentially functions as a wide and shallow beam. If the ratio of the longer span to the shorter span is higher than two, the slabs supported on all four corners behave as one-way slabs. The best way to identify a one-way slab is to look at a verandah, which has the main reinforcement running in one direction and the dissemination of reinforcement running in the other.

What is a two-way slab?

Slabs with support on each of their four sides are known as two-way slabs. Since the load will be converted in both directions in this slab, main reinforcement is offered for slabs in both directions. The two-way slab, which carries the load by bending in two perpendicular directions, has a ratio of less than two for a longer span to a shorter span. The floors of multistory buildings are the best example of a two-way slab.

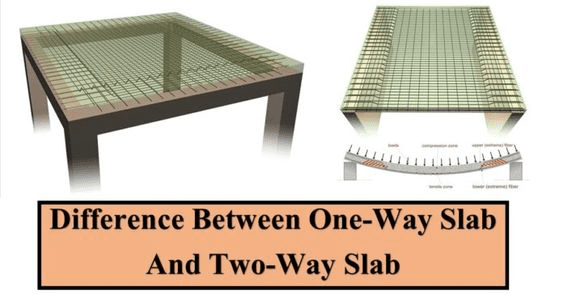

Types of slabs: Difference between a one-way slab and a two-way slab

Source: Pinterest

- The main reinforcement bars are located in both directions on the two-way slab. In contrast, the reinforcement bars in the one-way slab run parallel to the shorter side.

- We can see that the type of deflection in the one-way slab is a cylinder, while in the two-way slab, it has a slight bend. The two slabs differ from one another in this way, as do their deflections. By examining the type of deflection in the slab, it is a useful method for determining the type of slab. It provides information about the slab’s nature.

- The one-way slab’s thickness is increased as a result of using less steel in it. On the other hand, the two-way slab has more steel, which causes it to be deeper. The thicknesses of the two slabs are different in this way.

- The one-way slab has some uses in verandas and cantilever slabs. Similar to the one-way slab, two-way slabs are used for imaginative floorings, such as decorative rooms or multi-story buildings.

How to calculate a one way or two way slab?

If the L/b ratio is equal to or greater than 2, it is considered a one-way slab. On the other hand, if this ratio is less than 2, it is considered a two-way slab.

How specific load types influence slab design?

In structural engineering, understanding how different load types—dead loads, live loads, and dynamic loads—affect slab design is crucial for ensuring safety and performance.

Dead loads

Dead loads are permanent, static forces resulting from the weight of the structure itself and any fixed components, such as walls, floors, and built-in fixtures. These loads remain constant over time and are relatively straightforward to calculate. Accurate assessment of dead loads is essential, as they form the baseline upon which other loads are added. Underestimating dead loads can lead to insufficient structural support, while overestimating can result in unnecessary material usage and increased costs.

Live loads

Live loads are transient or movable forces that the structure must support, including occupants, furniture, vehicles, and equipment. Unlike dead loads, live loads can vary in magnitude and location. Designing for live loads requires considering the maximum expected load scenarios to ensure structural integrity. Building codes provide standard live load values for different types of structures and occupancies. For example, residential buildings may have a different live load requirement compared to commercial spaces. Properly accounting for live loads ensures that the slab can accommodate varying usage patterns without compromising safety.

Dynamic loads

Dynamic loads involve forces that change rapidly over time, such as those caused by machinery vibrations, vehicular traffic, or seismic activity. These loads can induce additional stresses and deflections in slabs, necessitating careful analysis. Designing for dynamic loads often requires incorporating factors like impact coefficients and dynamic amplification factors to account for the increased effects. Failure to adequately design for dynamic loads can lead to issues like excessive vibrations or even structural failure under certain conditions.

Minimum depth for a one-way slab

Deflection criteria, most of the time, dictate the minimum depth of a one-way slab. The minimum depth may occasionally be sufficient for flexure design purposes. Still, if the diversion criteria are not met, such slabs will vibrate even under light loads like walking, jumping, etc. Therefore, always check for deflection even though your layout checks may give you less depth. Here, you can provide a slightly greater depth and reduce steel to reduce costs overall. Please be aware that building occupants never experience vibrations as a sense of security.

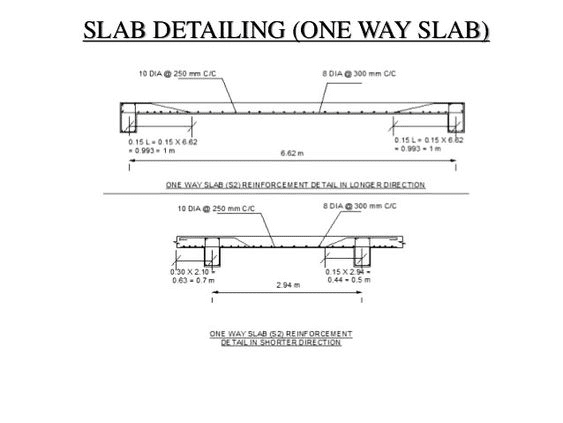

Source: Pinterest

One-way slab: Types

One-way solid slab with beams

The beams support the slab in a one-way solid slab (with beams) system. The said system can be created to handle various load conditions depending on the arrangement of the beams and columns.

One-way ribbed slab (with beams)

Low-rise office buildings, parking garages, and warehouses use the one-way ribbed slab (with beams) system.

One-way ribbed slab with integral beams

The one-way ribbed slab has a broader span than a solid slab. The one-way ribbed slab is cost-effective when used as a modular or prefabricated structure.

One-way slab: ISC requirement for slab design

Compressive strength

Based on the following factors, concrete’s compressive strength is determined.

- Based on the structure under consideration’s needs for strength.

- Based on the structure’s needs for durability. Sometimes, concrete with high compressive strength is required due to durability requirements.

The bar size

The bar size should be chosen so that the actual distance is not less than approximately 1.5 times the thickness of the slab to avoid paying too much for the fabrication and handling of the bars. Additionally, straight bars are typically used for slab reinforcement to lower costs.

Steel bars must have a certain distance between them

- Except for those used only to control shrinkage and heat cracks, the maximum lateral spacing of the bars should not be greater than three times the thickness (h), or 450 mm, whichever is less.

- The maximum distance between reinforcement bars for shrinkage and temperature is five times the thickness of the slab, or 450 mm, whichever is less.

- The minimum separation is equal to either 4/3* the maximum aggregate size or 25 mm, the diameter of a steel bar.

Common construction mistakes in one-way slabs

While one-way slabs are straightforward in design, real-world construction often introduces errors that compromise strength, durability, and safety. Especially on Indian sites where supervision may be limited, the following mistakes are commonly observed:

- Improper bar alignment or spacing

Site workers sometimes misplace or unevenly space the main and distribution bars, especially when formwork is congested. This leads to uneven load distribution, potential cracking, and reduced flexural capacity. It is critical to follow the exact bar spacing as per structural drawings and ensure bars are tied firmly to avoid shifting during concrete pouring. - Inadequate curing, especially in peak summer

Curing is essential to achieve full strength and minimize surface cracking. In hot weather, slabs dry too quickly, leading to plastic shrinkage cracks and reduced long-term durability. Builders often skip the required 7–14 days of moist curing. Methods like ponding, wet burlap, or curing compounds should be used consistently. - Premature removal of formwork

Removing centering supports before the slab gains sufficient strength leads to deflection or even collapse. As per IS 456:2000, formwork for slabs should typically remain for at least 7 days (longer in cold weather). Early removal is a critical error in fast-paced projects. - Use of low-grade or improperly mixed concrete

Though M25 concrete is often specified, on-site mixing sometimes results in subpar grades due to poor water-cement ratio control, ungraded aggregates, or improper batching. This severely affects compressive strength. For better quality assurance, use RMC (Ready Mix Concrete) where possible or ensure site mixes are tested regularly.

Practical applications of one way slab

Understanding the practical applications of one-way and two-way slabs is essential for selecting the appropriate structural system for various building types.

One-way slabs

One-way slabs are designed to carry loads primarily in one direction and are supported on two opposite sides. This design makes them suitable for:

- Residential buildings: Commonly used in single-story homes and low-rise apartments, one-way slabs are ideal for floors and roofs with shorter spans.

- Commercial structures: In small commercial buildings with straightforward layouts, one-way slabs provide an economical flooring solution.

- Industrial facilities: For warehouses and factories with uniform load requirements and shorter spans, one-way slabs offer simplicity and cost-effectiveness.

When not to use a one-way slab

While one-way slabs are cost-effective and simple to construct, they are not suitable for all building layouts or structural demands. Knowing where not to use them is just as important as understanding their benefits.

- Irregular or nearly square rooms (L/b < 2)

One-way slabs are designed to span in a single direction, which makes them inefficient in rooms where the length-to-breadth ratio is less than 2. In such cases, a two-way slab is more structurally sound and economical, as it distributes loads in both directions. - Areas with concentrated or point loads

One-way slabs are ideal for uniformly distributed loads but perform poorly under concentrated or heavy point loads—such as those from columns, heavy machinery, or storage racks. These scenarios require slab systems with stronger multidirectional reinforcement like flat slabs or waffle slabs.

3. Seismic zones requiring multi-directional stiffness

In earthquake-prone regions, structural systems must provide resistance in both directions to handle lateral loads and vibration. One-way slabs lack this dual-direction rigidity and are therefore avoided in seismic zone designs unless used in combination with additional reinforcement strategies.

What material should you choose for one way slabs

Selecting appropriate materials for slab construction is crucial, as it directly influences both durability and cost.

Concrete types

Concrete is classified into various grades, each denoted by an ‘M’ followed by a number indicating its compressive strength in megapascals (MPa).

- M15 and M20: These grades are suitable for non-structural elements like pathways and patios. They are cost-effective but offer lower strength.

- M25 and above: Grades such as M25 are commonly used in structural components, including slabs, beams, and columns, due to their higher strength and durability.

Choosing a higher-grade concrete enhances the slab’s load-bearing capacity and longevity but increases material costs.

Steel reinforcement grades

Steel reinforcement bars (rebars) are essential for providing tensile strength to concrete slabs. Common grades include:

- Fe 415: Offers a yield strength of 415 MPa and is suitable for most residential constructions.

- Fe 500 and Fe 550: Provide higher yield strengths of 500 MPa and 550 MPa, respectively, making them ideal for structures requiring greater load-bearing capacity.

Utilizing higher-grade steel can reduce the quantity of reinforcement needed, potentially offsetting the increased material cost.

Impact on durability and cost

- Durability: Higher-grade materials improve resistance to environmental factors, reducing maintenance needs over time. For instance, using M25 concrete enhances durability compared to M15.

- Cost: While premium materials elevate initial expenses, they often lead to long-term savings through decreased repair and replacement costs.

FAQs

One-way slab theory: what is it?

The imposed loads are only transferred in one direction by one-way slabs. Only two of their opposing sides may be supported, in which case the systemic action is primarily one-way, and the loads are carried parallel to the supporting walls or beams.

Which way is the primary reinforcement in a one-way slab provided?

The primary reinforcement is positioned parallel to the slab's shorter direction. On the other hand, the main reinforcement is positioned parallel to the supports if the slab is only supported on two sides. The distributed or secondary reinforcement is positioned across from the primary reinforcement.

Why is one-way slab used?

A one-way slab is employed when load transfer predominantly occurs in a specific direction, referred to as the span. This type of slab is specifically designed to withstand bending forces in only one direction. As a result, the primary tension-reinforcing bars are uniformly spaced and run parallel to the shorter span, typically positioned at the slab's bottom.

What is the ratio of one-way slab?

In the case of a one-way slab, the ratio of the longer span panel (L) to the shorter span panel (B) should be equal to or greater than 2.

What size is a one way slab?

One-way slab concrete floors come in various sizes, accommodating conventional spans ranging from 6 to 20 feet (1.83 to 6.1 meters) and post-tensioned spans spanning from 13 to 28 feet (3.96 to 8.53 meters). The depth of these slabs typically falls within the range of 4 to 10 inches (10.2 to 25.4 centimeters), determined by applying the span-to-depth formula, which divides the span by 30.

What is the maximum span of a one-way slab?

In general, a one-way RCC (Reinforced Cement Concrete) slab, without the inclusion of beams, should not exceed a maximum span of 3.5 meters. This span limitation is an important consideration for ensuring structural integrity and safety.

| Got any questions or point of view on our article? We would love to hear from you. Write to our Editor-in-Chief Jhumur Ghosh at jhumur.ghosh1@housing.com |