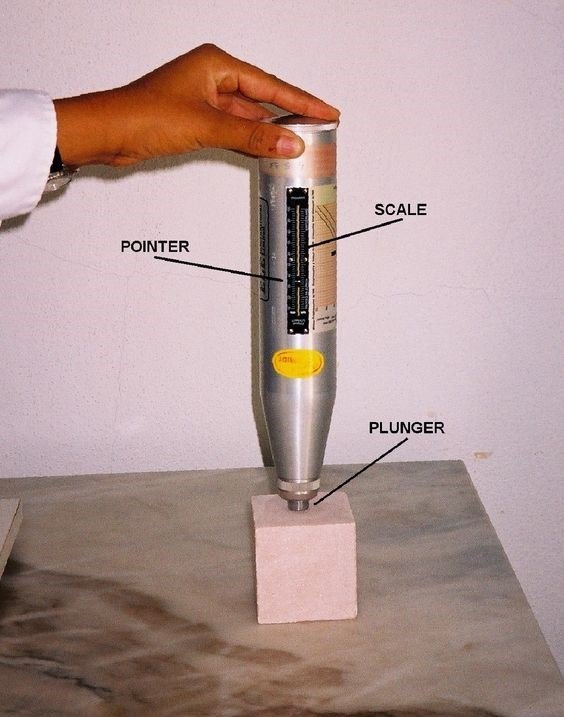

The concrete’s compressive strength can be quickly and easily determined with the use of the non-destructive rebound hammer test. Rebound hammers, also known as Schmidt hammers, are made out of a spring-controlled mass that travels down a plunger inside of a cylindrical casing.

What is a rebound hammer?

There are a few other names for a Concrete Test Hammer, including Swiss Hammers, Schmidt Hammers, and rebound hammers. They are multipurpose tools that are used to evaluate the quality of hardened concrete. Even though their primary purpose is to determine the in-place compressive strength, concrete test hammers have much more to offer.

Strength is not the only factor that should be considered when assessing a concrete building or pavement. The hammers are portable and simple to use, and the fact that they have been widely used for such a long time implies that their performance and outcomes have been well studied.

Source: Pinterest

Who came up with the rebound hammer?

Ernst O. Schmidt, a civil engineer in Zurich, Switzerland, is credited with inventing the concrete test hammer in the year 1954. Antonio Brandestini, who created the Swiss business Proceq, is credited with developing the device for commercial use via Proceq.

What is the rebound hammer test?

The rebound hammer test excels in the quick and effective collection of data on the quality and homogeneity of concrete in newly constructed buildings and those already built. A straightforward testing procedure provides an overall image of the concrete’s condition, draws attention to parts with reduced strength, and singles out regions that have been damaged by freezing or fire. It is easier to get accurate values of compressive strength using correlation data from laboratory experiments.

By striking hardened concrete with the test hammer’s piston, a spring mechanism is loaded until it trips, releasing the hammer mass. A predetermined quantity of energy is transferred from the mass when it hits the piston to the concrete. A simple linear scale records the rebound number (R-value) as the hammer mass slides along an indicator. When compared to findings from laboratory tests, Schmidt discovered that these surface hardness values might reflect relative strength.

What is the purpose of the rebound hammer test?

The rebound hammer test is designed to accomplish the following goals, as specified by the Indian code IS: 13311(2)-1992:

- To establish the concrete’s compressive strength by establishing a relationship between the rebound index and the compressive strength.

- To evaluate how consistent the concrete is.

- To determine the quality of the concrete following the standard requirements.

- To compare the qualities of one particular element to those of another element.

The technique of the rebound hammer can be used to distinguish between the portions of the construction that are acceptable and those that are problematic 9and to compare the strengths of two distinct structures.

Performing a rebound hammer test on concrete

The procedure of rebound hammer test on concrete structure begins with calibration of the rebound hammer. For this purpose, the rebound hammer is tested against the test anvil designed of steel. It is then held at right angles to the surface of the concrete structure for taking the readings. The rebound hammer test can be conducted horizontally on a vertical surface and vertically upwards or downwards on horizontal surfaces.

Things to keep in mind during the rebound hammer test

- The surface of the concrete must be smooth, clean, and dry.

- Before conducting a hammer test, any loose particles on the surface of the concrete should be removed using a grinding wheel or stone.

- It is not recommended to perform the rebound hammer test on rough surfaces such as those caused by inadequate compaction, loss of grout, or spalled or tooled concrete surfaces.

- It is recommended that the point of impact of a rebound hammer on the surface of concrete be at least 20 millimetres away from any edge or form discontinuity.

- At each point of testing, six readings of the rebound number are obtained, and the value of the average of these readings is used to calculate the rebound index for the point of observation on the concrete surface that corresponds to the reading.

Methods for choosing and preparing testing locations

- Care must be taken while choosing and preparing test locations since wetness, surface quality, age, carbonation depth, and closeness to aggregate, steel reinforcement, and air voids all have a direct impact on rebound figures.

- Concrete with a high moisture content has lower rebound readings than the same concrete when dry. A few hours before taking rebound data, the test surface should be wet with water if measuring compressive strength by correlation with cores or cylinders. Saturated, surface-dry (SSD) conditions should be used to evaluate the correlation samples.

- Since the rebound number is a measure of surface hardness, testing on textured or soft surfaces requires surface preparation. Manually using a carborundum stone to smooth the surface is usually sufficient, although a surface grinder may be necessary for specific places. Rebound testing does little harm to the concrete and often leaves little dimples on the surface.

How should one work with the rebound hammer?

The rebound hammer is an extremely user-friendly piece of testing equipment, but it is necessary to fulfil many prerequisite requirements before beginning the testing process to get accurate and consistent results.

Preparation of test surface

Before carrying out a rebound hammer test, inspectors should have a keen awareness of the following factors to take into account:

- At least 150 millimetres in diameter must be present on the testing surface.

- If the surface of the concrete is extremely textured or includes loose mortar, it should be ground (until it is flat).

- Before any testing can be done, any free moisture or water that is present on the surface of the concrete has to be removed.

- Do not test frozen concrete. Because frozen concrete has a tendency to have high rebound figures, it is important to note that testing concrete should only be done after it has thawed.

- When the cover thickness is less than 20 millimetres, direct testing over the steel reinforcement should be avoided. To prevent testing on reinforcement with a shallow depth, it is advisable to make use of a rebar locator.

The direction of the rebound hammer

The first step in conducting a successful rebound hammer test is for the inspector to take a firm grip on the instrument and position the plunger so that it is perpendicular to the surface being examined. The angle of the instrument relative to the horizontal must also be noted to the closest 45 degrees. A positive angle should be used if the instrument is pointed upwards, and a negative angle should be used if the instrument is pointing downwards.

Taking readings

After the device has been aligned and the angle has been recorded, the inspector will gently move the instrument closer to the surface being tested until the hammer makes contact with the surface. After the impact, you should continue to apply pressure on the instrument while also depressing the button on the side of the instrument to secure the plunger in the retracted position.

The accuracy of the results relies on taking a minimum of 10 separate readings from each test region. Further, at least 25 mm should separate impact locations, and at least 50 mm should separate impact sites and member edges. If the impact causes the crushing or breaking of an air void close to the surface, the measurement must be discarded and a new reading recorded.

Applications of rebound hammer test

The most common use for a rebound hammer is in the process of determining the relative hardness of concrete by using the concept of the rebound. Despite this, scholars have attempted to use the approach to evaluate a variety of tangible characteristics. The following are examples of applications that are very common:

- Determine how consistent the concrete is where it is placed.

- Delimit areas within a structure that are made of concrete that is of low quality or has deteriorated.

- As a technique for estimating the strength of concrete while it is still in situ

Pros and cons of rebound hammer test

The use of a rebound hammer to determine the strength of concrete has been and continues to be the subject of debate among these applications. When it comes to determining the strength of concrete through the use of a rebound hammer, researchers have different opinions.

Pros

- The apparatus is simple to use.

- Identifies the surface’s attributes of homogeneity and consistency.

- The equipment that is utilised is reasonably priced.

- Used in the restoration of historic buildings and structures.

Cons

- The findings are based on the local point.

- The findings of the tests do not have a direct bearing on the surface’s tensile strength or its deformation capacity.

- It will be necessary to do routine cleaning and maintenance on the probe and spring arrangement.

- It is not possible to identify flaws with precision.

What affects the results of a rebound hammer test?

Aggregate type

Using various aggregates will alter the relationship between concrete’s compressive strength and its rebound number. The usage of standard aggregates, such as gravels and crushed aggregates, yields standard correlations in the findings. Lightweight aggregates in concrete will need individualised adjustment so that the material can pass the test.

Cement type

When compared to concrete created with regular portland cement, concrete made with high alumina cement should have greater compressive strength. The compressive strength of concrete made with super sulphated cement is reduced by half compared to that of concrete made with ordinary Portland cement.

Surface type and moisture condition

The rebound hammer test is more accurate when applied to concrete with a close texture than concrete with an open texture. It is not possible to use a rebound hammer to evaluate the strength of concrete that has a significant number of honeycombs or no fines.

In comparison to testing on moulded surfaces, floating or trowelled surfaces result in an overestimation of the material’s strength when subjected to the same test. If the wet concrete surface is tested, the result will show that the strength is decreased. It’s possible to underestimate the concrete’s strength by as much as 20% compared to when it’s dry.

Curing and age of concrete

The relationship between the concrete’s strength and its level of hardness will shift over time. The circumstances under which concrete is allowed to cure and the conditions under which it is exposed to moisture also impact this connection. The impact of age does not take effect on concrete that has been aged for three days or more but less than ninety days. To account for increasing amounts of old concrete, specifically calibrated curves are required.

Carbonation on the surface of the concrete

When used with concrete that has been carbonated, the rebound hammer provides an estimate of the material’s increased strength. It is expected to be 50% more than that. Therefore, to complete the test, you will need to remove the carbonated layer from the concrete and perform the test using a rebound hammer on the layer of concrete that has not been carbonated.

Observations about the rebound hammer test

- Schmidt’s invention of the rebound hammer offers a way for the non-destructive testing of concrete that is both rapid and does not cost too much money.

- When employing the rebound hammer, it is important to acknowledge and take into consideration the constraints imposed by the testing technique.

- It is of the utmost significance to emphasise that the hammer should not be considered an alternative to the conventional compression tests but rather as a technique for determining the uniformity of the concrete used in the structures, contrasting one type of concrete with another, and cutting down on the number of core samples to be taken.

FAQs

What is the accuracy of the rebound hammer test?

The findings indicate that the prediction of compressive strength using a rebound hammer was correct in the range of 48 to 58 MPa with an error of 15.32%, but tend to underestimate the actual sample strength in the higher and lower areas.

How should the findings of the rebound hammer test be interpreted?

In general, the rebound number rises with increasing strength and is also impacted by a multitude of variables, such as the cement type, condition of the surface, moisture content, age of concrete, carbonation of the concrete surface, and so on.

How are rebound hammer results calculated?

The outcome of the rebound hammer test is determined by graphing the data acquired from the rebound hammer number and the concrete's compressive strength. The precision of the result may vary by 25% according to the concrete's compressive strength.

To what extent does the Q value matter in a rebound hammer test?

All available concrete testing hammers have this characteristic. The Q value is obtained by the Silver Schmidt by measuring the impact velocity (V) and the rebound velocity just before and after the impact. There is no need to account for impact direction while calculating Q.

What are the safety considerations when using a rebound hammer?

Use appropriate personal protective equipment such as gloves and safety glasses while using rebound hammer. Also ensure that the area is clear of debris and that there are no other hazards present that could cause injury.

List applications of a rebound hammer

Rebound hammer is used in the construction industry to assess the quality of concrete structures like buildings, bridges, and tunnels. It can also be used to evaluate the strength of other construction materials such as masonry, rock and asphalt.

Housing News Desk is the news desk of leading online real estate portal, Housing.com. Housing News Desk focuses on a variety of topics such as real estate laws, taxes, current news, property trends, home loans, rentals, décor, green homes, home improvement, etc. The main objective of the news desk, is to cover the real estate sector from the perspective of providing information that is useful to the end-user.

Facebook: https://www.facebook.com/housing.com/

Twitter: https://twitter.com/Housing

Email: editor@housing.com