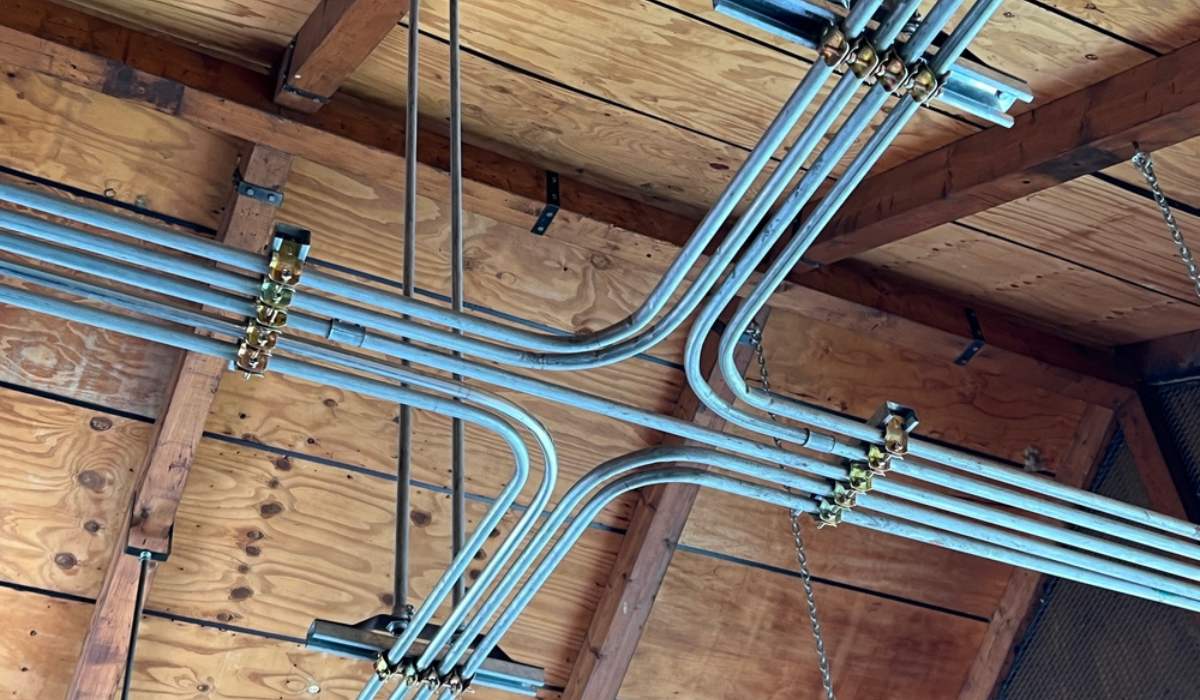

Surface conduit wiring is a popular method of electrical wiring where the conduits are mounted on the surface of walls or ceilings, as opposed to being embedded within them. This type of wiring is often chosen for its flexibility, ease of installation, and the ability to modify or expand the electrical system without significant disruption. In this comprehensive guide, we will explore the components, installation process, advantages and safety considerations associated with this.

See also: Casing Capping Wiring: Types, Benefits, and Disadvantages

What are the components of surface conduit wiring?

Conduits

Conduits are hollow tubes made of metal, plastic, or a combination of both materials. They serve as protective channels for electrical wires, shielding them from physical damage and environmental factors. Conduits can be rigid or flexible, depending on the application.

Wiring

Electrical wires, typically made of copper or aluminium, run through the conduits. These wires conduct electrical current and are insulated to prevent short circuits and ensure safety.

Boxes

Junction boxes or conduit boxes are used to contain wire connections and provide access points for maintenance or future installations. They come in various sizes and types, including standard junction boxes, switch boxes and outlet boxes.

Fittings

Fittings are used to connect conduits to boxes, each other or to change the direction of the conduit. Common fittings include elbows, couplings, connectors and straps.

Fixtures and devices

It is often associated with fixtures such as switches, outlets and lighting devices. These elements are connected to the wiring system and mounted on the surface of walls or ceilings.

What is the installation process?

Planning

Before installation, create a wiring plan to determine the placement of conduits, boxes, and devices. Consider the electrical load, circuit requirements, and aesthetic preferences.

Marking and mounting

Mark the locations for conduits, boxes, and devices on the walls or ceilings. Secure the conduits using appropriate fasteners and mount the boxes at specified points.

Cutting and bending conduits

Cut conduits to the required lengths using a conduit cutter. If necessary, bend the conduits using a conduit bender to navigate corners or obstacles.

Connecting conduits and boxes

Use fittings to connect conduits and junction boxes. Ensure a secure fit and proper alignment for efficient wire routing.

Installing wires

Thread the electrical wires through the conduits, ensuring proper insulation and colour coding. Connect wires to devices and secure them within the junction boxes.

Testing

Before closing the system, conduct thorough testing to ensure proper connections, polarity, and functionality. Use a voltage tester to check for live wires and ensure safety.

What are the advantages of surface conduit wiring?

Flexibility

Surface conduit wiring allows for easy modifications and additions to the electrical system without the need for major renovations.

Accessibility

Junction boxes provide easy access to wiring connections, making maintenance and troubleshooting simpler.

Aesthetics

Conduits can be chosen to complement the design of the space, and the visible wiring can be arranged neatly for a clean and industrial look.

Cost-effective

Surface conduit wiring is often more cost-effective than concealed wiring due to reduced labour and material costs.

What are the safety considerations?

Proper insulation

Use wiring with proper insulation to prevent electrical shocks and short circuits. Ensure that all wires are properly insulated to prevent electrical shocks and short circuits.

Secure mounting

Conduits and boxes must be securely fastened to the walls or ceilings. Use appropriate fasteners and mounting hardware to prevent sagging or displacement over time, especially in areas with vibration or movement.

Compliance with codes

Follow electrical codes and regulations applicable to your region. Compliance ensures that the installation meets safety standards and is less likely to pose hazards.

Professional installation

For complex installations or if unfamiliar with electrical work, it is advisable to hire a licensed electrician to ensure safety and code compliance.

Avoid overloading

Conduct a thorough analysis of the electrical load to avoid overloading circuits. Distribute the load evenly and use the correct wire sizes for the intended purpose.

What are the disadvantages of surface conduit wiring?

Vulnerability

Surface-mounted conduits are more susceptible to physical damage compared to their concealed counterparts. They can be easily bumped, dented, or otherwise impacted, exposing the wiring within and potentially compromising safety.

Limited concealment

The wiring is visible and may be more challenging to conceal, making it less suitable for locations where a seamless and hidden appearance is desired.

Dust and dirt accumulation

Over time, dust and dirt can accumulate on the surface of conduits and boxes, requiring regular cleaning to maintain a tidy appearance.

Space limitations

Surface conduit wiring may take up valuable wall or ceiling space, limiting design options and potentially conflicting with other installations or decorations.

Temperature sensitivity

In areas with extreme temperature variations, surface conduit wiring may be more prone to temperature-induced expansion and contraction, potentially affecting the integrity of the installation over time.

Installation complexity

While surface conduit wiring is generally simpler to install than concealed wiring, complex configurations or intricate designs may pose challenges and require careful planning.

Not ideal for all environments

Certain environments, such as high-humidity areas or locations with corrosive substances, may not be suitable for surface conduit wiring as it may be more prone to environmental damage.

FAQs

How is surface conduit wiring different from concealed wiring?

Surface conduit wiring is visible and mounted on the surface, while concealed wiring is hidden within the walls or ceilings.

What are the advantages of surface conduit wiring?

Advantages include flexibility for modifications, easy accessibility for maintenance, aesthetic options, cost-effectiveness, and simplified installation.

Are there any disadvantages to surface conduit wiring?

Yes, disadvantages may include aesthetic concerns, vulnerability to physical damage, limited concealment, potential dust accumulation, and space limitations.

Is surface conduit wiring suitable for residential applications?

Yes, surface conduit wiring can be used in residential settings, but the aesthetic preferences of homeowners should be considered.

What materials are commonly used for conduits in surface wiring?

Conduits can be made of metal (such as steel or aluminium), plastic, or a combination of both materials.

How is the wiring routed through conduits?

Electrical wires are threaded through the conduits, and fittings like elbows and connectors are used to navigate corners and connect conduits.

Is surface conduit wiring safe?

Yes, if installed correctly and in compliance with electrical codes, surface conduit wiring can be safe. Proper insulation, grounding, and secure mounting are essential for safety.

| Got any questions or point of view on our article? We would love to hear from you. Write to our Editor-in-Chief Jhumur Ghosh at jhumur.ghosh1@housing.com |