Screws are, without a doubt, essential tools for any building or maintenance task. A screw has a long shaft and a slotted head with helical threads winding around it, and it is a small, sharp-pointed metal tip used to twist items together to form joints. They enable the assembly of parts that you can quickly disassemble.

A screw’s two main uses are lifting or holding things together. An effective tool for keeping things together is a screw, which has to thread around its shaft. The threads form a tight grasp on the surrounding medium, like teeth. Read the article to learn more about the various screws and their applications.

Selecting the correct screw types

Machinery screws come in a variety of materials as well. You can use a drywall screw with a piece of wood, but it does not always imply it is the ideal choice. The importance of selecting the correct screw cannot be overstated.

Protection: Their design protects the materials that screws are used to link. It is possible to prevent metal from slipping, drywall from drooping, and wood from breaking by using screws with the proper head, length, and thread.

Usefulness: It should not be difficult to fasten materials, so choosing the right screw is crucial. You should use the correct drill, impact driver, wrench, or screwdriver to drive screws through the proper materials quickly.

Size: Length is the most crucial consideration when choosing a screw. According to the general rule of thumb, you should insert the screw halfway through the bottom material, for example, 3/4′′ into a 2 x 4. The screw’s gauge or diameter is an additional consideration. Screw gauges range from 2 to 16. The majority of the time, you should use a #8 screw.

Material: Choosing a screw that will keep materials together is critical because screws are made with materials in mind. A wood screw will not provide a secure grip in masonry, and a threaded screw holds differently than a partially threaded screw.

Safety: By using the suitable screw for the work, you can ensure that the materials are held in place and that you are not at risk for problems like screw corrosion, split wood, defective joints, or other safety issues.

Type of screws

Lag screws

The length and high diameter of lag screws and carriage screws allow them to enter wood or other materials deeply. Tag screws are extraordinarily durable and covered in a corrosion-resistant coating to prevent deterioration from environmental exposure or further construction corrosion. They are frequently used in decks, walls, and other outside buildings to make robust connections.

Lag screws hold significant pieces of wood together; however, carriage screws are more secure and are utilised for this purpose. They are also tamper-proof due to their rounded heads, making them perfect for outside structures in public areas. Lag screws frequently need other tools and a pre-drilled pilot hole to be driven into the material.

Source: Pinterest

Timber screws

Wood screws are used to attach various pieces of wood and are undoubtedly the most popular screw among DIYers. They often have a sharp, penetrating tip that quickly penetrates wooden surfaces, and they can have a fully or partially threaded shaft. Because of this, most wood screws do not need a pilot hole.

For any DIY tasks, it is simple to locate these screws at a nearby home improvement store. You can choose from various sizes and drives to meet your demands but use these screws exclusively with wood. The threads must be closer together to grip concrete or other non-fibrous surfaces effectively.

Source: Pinterest

Drywall screws

This kind of screw comes in lengths of 1 to 3 inches and is solely meant to hang drywall panels. The name “bugle head screw” comes from how their “bugle” head is made to countersink slightly into the drywall panel’s surface without ripping the panel’s protective paper coating. It is not essential to drill holes beforehand because as these self-tapping screws get close to the wood joists or studs, they sink in.

When attaching drywall panels to wood framing, standard drywall screws work well. However, if you are hanging drywall over metal studs, search for screws designed for that purpose.

Source: Pinterest

MDF screws

Medium-density fiberboard screws are among the most widely used screws. They are frequently seen in homes in moulding, crown moulding substitutes, and the building of shelves and bookshelves (especially those that need assembly). These screws are incredibly durable since MDF is a substance that is much more difficult to pierce than solid wood and is more demanding than those screws. Unless you first pre-drill a hole and then use a regular wood screw, using wood screws on MDF will almost always result in splitting.

MDF screws make life simpler, mainly when using self-tapping ones. MDF screws are designed to prevent splitting and the requirement for pre-drilling. The exact sizes as standard wood screws are offered, and they have star-drive heads.

Source: Pinterest

Nut head screws

Similar to oval head screws, these have flat heads with two rounded edges and are mainly employed as machine screws. These are available in various sizes and shapes. It can be installed using just a screwdriver and is typically employed in applying metal elements when the tapered side remains on the underside of the head.

Source: Pinterest

Pan head screws

Pan head fasteners come in three different categories:

- Square pan head

- Phillips pan head

- Phillips pan framing

They are often made of zinc coated in steel to prevent rust and increase their lifespan. However, the pricing range for these is flexible because different businesses are developing a range of product possibilities.

Source: Pinterest

Slotted screws

Due to their single, tiny aperture for a flat screwdriver, slotted head screws are more commonly known as flathead screws. Even though this kind of screw is one of the most widely used and least expensive, it is also the most likely to strip. Slotted screw are intended to strip so that you will not overtighten them. This trendy style, frequently used with manual screwdrivers, has a straight line running through the centre of the screw head.

Instead of using a powered drill, which frequently results in the screw stripping or coming out, slotted screws are suitable for applications that call for a few screws that you can screw manually.

Source: Pinterest

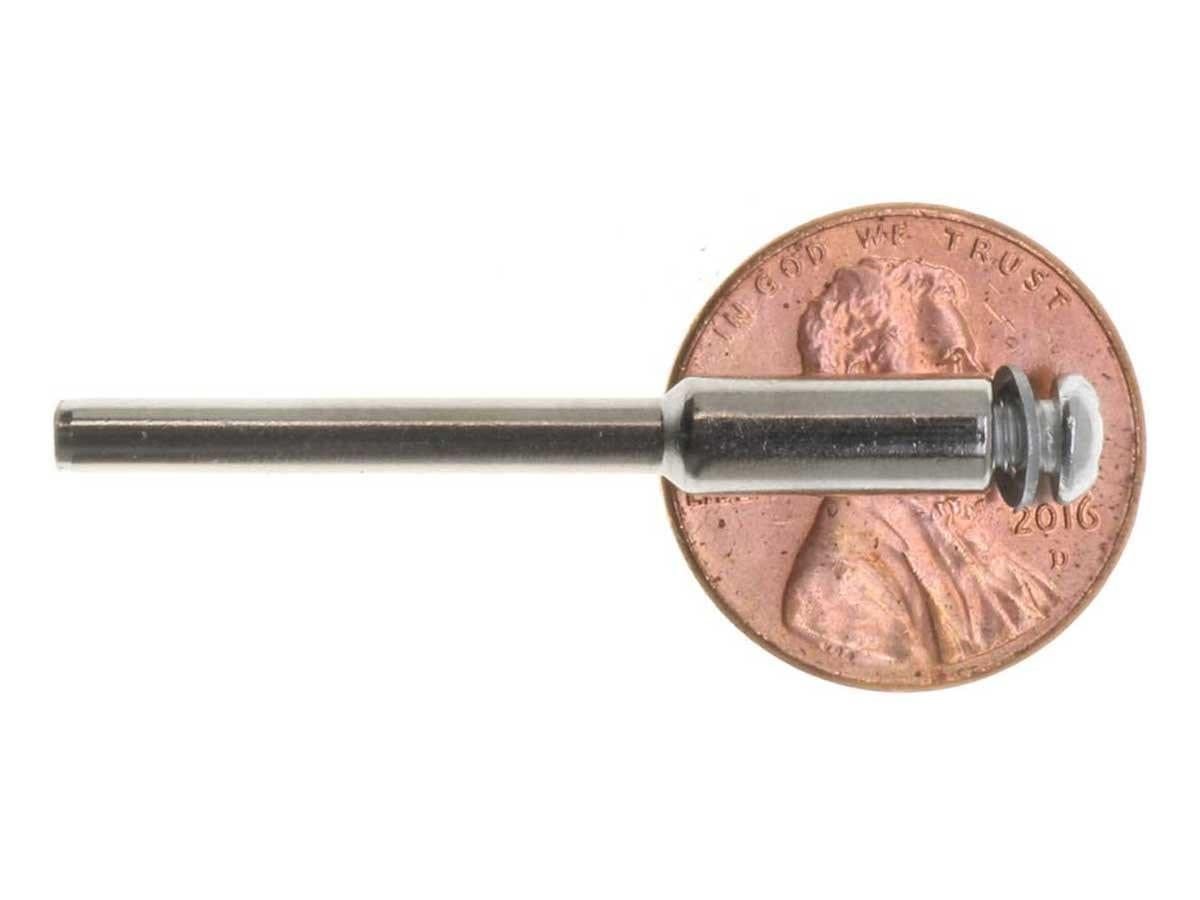

Mirror fasteners

These screws are made specifically for attaching mirrors to walls and have tapered rubber grommets to stop the metal screws from pressing into the mirror. To support the mirror, you can use this particular kind of screw, which has a slotted, countersunk head with a threaded hole so that the cover cap can be threaded into the hole.

Anywhere in the house, including the bathroom, these screws can be used. The additional moisture and humidity in the bathroom or kitchen are not a concern because the stainless steel construction and zinc coating prevent rust and corrosion.

Source: Pinterest

Metal screws for sheet

As their name implies, sheet metal screws are made for fastening metal sheets. Although you can use them for wood or join other materials, their main application is sheet metal. To ensure that they can readily drive through the sheet metal, this type of screw often has threading up to the head and does not have a smooth shaft.

These screws are typically constructed of steel and have a self-taping mechanism that makes them strong and lasting. These robust screws, which come in various sizes and have sharp tips and flat or hex heads, are adaptable and dependable.

Source: Pinterest

Hammer-drive screws

Hammer-drive screws, also known as U-drive screws, non-slotted round-head screws, or drive screws, are made for heavy-duty fastening. They are powerful, long-lasting, and last you for a long time because of their rounded heads and distinctive construction.

Nameplates, wall signage, and similar items are typically fastened with hammer-drive screws. They also have substantial helical angles, several start threads, and an unthreaded pilot point. To swiftly and securely install these screws, utilise standard hammers, mallets, or hammer-drive tools. The screw needs to be manufactured of a more rigid material than the component you plan to drive it into, and you might need to use a smaller-than-needed pre-drilled pilot.

Source: Pinterest

Pocket screws

Wood is joined with pocket hole screws in a pocket hole that has already been drilled. Because they may be concealed, pocket holes are frequently employed when making furniture and cabinets. They offer one of the most secure methods of joining materials when paired with a pocket hole jig. There is no need to drill pilot holes before attaching two pieces of fabric because the screw has a self-tapping head that creates its spot.

This screw’s square drive prevents peeling even with a rapidly spinning drill and snugly accepts a driver (drill bit for a screwdriver). The driver’s square shape makes it unlikely to come loose from the screw’s recess. Pocket screws must be strip-proof because they are concealed inside pre-drilled pocket holes, and it can be challenging to remove a stripped screw from there.

Source: Pinterest

DIY projects

Home repairs

Furniture assembly

Metalworking

Woodworking

FAQs

How can you calculate a screw's diameter?

Calculate the distance between the exterior line on one side and the external thread on the other to measure the dimension of bolts and screws.

How deeply should a screw get in wood?

The basic guideline is that the screw should penetrate the lower piece by about two-thirds of its length.

What distinguishes screws from bolts?

A bolt is an assembly made up of a screw and nuts as opposed to a screw, which is a threaded rod.

| Got any questions or point of view on our article? We would love to hear from you. Write to our Editor-in-Chief Jhumur Ghosh at [email protected] |

Saswat Kumar, a real estate writer, keeps up with the latest trends in residential real estate. He simplifies complex real estate jargon, making it accessible to all. Saswat’s data-driven analysis empowers buyers and investors to make informed choices in the housing market.