What is guniting?

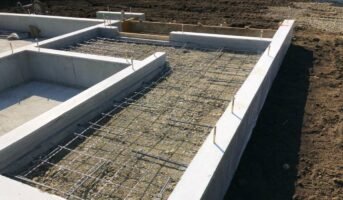

Guniting is the process of using a spray gun for applying mortar or concrete to a surface. This process is mainly used for slope stability and specific rehabilitation purposes in building retaining walls, pools, tunnels, swimming, fluid tanks and some concrete restoration projects.

The dry Shotcreting technique is also known as guniting. Guniting and shotcrete differ in this way. Some nations only use the term “dry shotcrete” instead of “gunite,” which is only a trademark.

What is the procedure of guniting?

- Guniting, also called the dry-mix shotcrete technology, utilises a nozzle to transfer dry material from a machine to the application’s surface under high velocity and compressed pressure.

- Water is added to the nozzle to facilitate application, and the final mixture that emerges is a mixture of water and dry material.

- Both the water addition and the total water content were under the operator’s control.

- Depending on the application and regional restrictions, the cement mortar mix may need to be modified.

- The dry components are combined and kept in a cement gun in a bin.

- The dry mix is injected at high pressure and velocity, and water is supplied to the nozzle just before the dry mix bursts off during application.

- The nozzle receives water at sufficient pressure from a water supply pressure tank.

Properties of guniting

- For guniting a good amount of cement is used, which increases durability, and also, small size aggregate is used.

- A high-speed jet impinging on the surface caused guniting to solidify, which helps to bring various air-void systems and increase the amount of cement. This whole process also impacts the durability of guniting.

- In comparison to mixing proportions, these techniques have a massive impact on in-place qualities of shotcrete properties.

Requirements for guniting

The following requirements are listed below:

- Through careful and skilled nozzle control, one can achieve high-quality completed work through guniting.

- Using a high-pressure water jet, the surface of the application must be cleansed and clear of any dirt, grease, or other defective materials.

- The reinforcement’s rust is removed from the application’s surface with sandblasting, and the fine aggregate employed in the mix has a size of 10 mm.

- The mix ratios utilised for guniting are 1:3 and 1:4:5.

- To reduce permeability, a top-notch mortar must be utilised along with strategies to increase resistance to weather and chemical attack.

Equipment used for guniting

- Guniting gun

- Concrete guniting machine

- Nozzle

- Hose

- Air compressor

- Admixture dispenser

- Pressure tank

Uses of guniting

The following are some applications for guniting:

- In addition to thin above vertical or horizontal surfaces, curved or folded portions, canals, reservoirs, and tunnel lining, it is used in many construction types.

- It has been utilised successfully to stabilise rock slopes and temporarily protect recently excavated rock surfaces.

- It is also utilised in water retention systems, swimming pools, and prestressed tanks.

- Steel building frames, oil tanks, coal bunkers, and other structures are also utilised to prevent long-term corrosion of pilling.

Precautions of guniting

Nozzle velocity: Higher velocities between the material granules in the nozzle and the rebound material cause an interaction that produces a porous mass with lesser strength. So, the nozzle velocity can not be more than 140 m/s.

Structure repair: Guniting must have a minimum thickness of 40 mm to be used for structural repair.

Water pressure: Water and air pressure should be between 0.45 and 0.67 N/mm2. Changes in air or water pressure cause a certain quantity of a too dry or too wet mix to be applied, giving the surface a splotchy appearance.

Guniting of walls: Guniting needs to start at the bottom when it comes to walls. The reinforcement should be covered entirely with the first gunite coating.

What are the advantages of guniting?

The dry-mix shotcrete procedure is a frequently utilised technique that offers the following advantages:

Flexible process: This technique can create structures with any shape, such as curves, spheres, or undulating surfaces. The main reason it is employed in swimming pools, caverns, waterfalls, etc. is its versatility, which enables the provision of unique shapes and characteristics. Due to this property’s use for refractory work, slope protection, tunnel lining, and numerous maintenance operations. These are used in various ways to build dams, reservoirs, bridges, pipelines, and canals.

Controllable process: Since it is incorporated into the mixture at the nozzle, you have control over the water. While performing the spraying technique, the crew can quickly regulate this adjustment. As a result, depending on the need, it will be feasible to provide a mix that is either moist or dry.

Fast process: The dry-mix shotcrete procedure, also known as the guniting mix, can be completed more quickly than the wet shotcrete method. These work better for the above applications because wet mix heights would produce issues like sagging, sticking, or segregation.

Use the dry-mix shotcrete technique (guniting) rather than the wet-mix shotcrete process for small projects like filling up small areas of cracks, applying thin linings or coatings, or applying delicate treatment.

Disadvantages of guniting

The following are some disadvantages of guniting:

High quality: To properly monitor the pressure, add the appropriate amount of water at the nozzle, and then apply a high-quality mix to the application surface, the guniting procedure will require highly trained and professional staff.

Rebound: The issue of the mix rebound will be dealt with during the guniting process. There is a potential that the contents will bounce off the surface of the material as the mixture is sprayed on it and then fall to the ground. It refers to this event as a rebound. Compared to wet-mix shotcrete, this occurs more frequently when guniting with dry-mix.

Conclusion

Guniting is one of the crucial processes for construction purposes. It is a swift, flexible process with all its goods. If you want to build stable retaining walls, tunnels, fluid tanks, and pools, this is the most needed process you should work on.

FAQs

What cement ratio is applied in the DPC Guniting method?

Guniting is a damp-proofing technique that uses pressure to apply a thick cement mortar layer to exposed walls and pipe surfaces. Typically, 1:3 cement-to-sand mortar is utilised for this purpose.

What distinguishes gunite and shotcrete?

These two materials are similar in terms of structure. However, when water is added to the mixture, the two components diverge most drastically. Water is incorporated into gunite on location. When using shotcrete, water is added before use.

How thick is guniting?

Layers of 40–50 mm thick gunite are applied during the guniting process.

What do guniting and grouting mean?

It is one method of groundwater control used in civil engineering projects. Typically, grouting is done by drilling or driving pipes into the ground and then pushing the grout solution through tubes placed at high pressure.

Why is guniting conducted?

It prevents dirt and other particles from getting between and beneath your tiles. The tile installation becomes more solid and robust as a result.

| Got any questions or point of view on our article? We would love to hear from you. Write to our Editor-in-Chief Jhumur Ghosh at [email protected] |

Housing News Desk is the news desk of leading online real estate portal, Housing.com. Housing News Desk focuses on a variety of topics such as real estate laws, taxes, current news, property trends, home loans, rentals, décor, green homes, home improvement, etc. The main objective of the news desk, is to cover the real estate sector from the perspective of providing information that is useful to the end-user.

Facebook: https://www.facebook.com/housing.com/

Twitter: https://twitter.com/Housing

Email: [email protected]