Construction equipment is used for many different purposes during large-scale and small-scale construction projects. The scope of the job and the budget available for the project are two of the primary considerations that guide the choice of construction equipment. These things make the building process simpler.

Different categories of construction equipment used in construction

The following is a list of the several kinds of construction equipment that are used quite often in the construction industry:

- Telehandlers

- Feller Bunchers

- Dump Trucks

- Pile Boring Equipment

- Pile Driving Equipment

- Excavators

- Backhoe

- Dragline Excavator

- Bulldozers

- Graders

- Scraper for Wheeled Tractors

- Trenchers

- Loaders

- Cranes Atop Towers

- Pavers

- Compactors

Telehandlers

Source: Pinterest

In the construction industry, hoisting equipment known as telehandlers are used to carry heavy objects to the proper height, offer a construction platform for employees located at higher heights, and perform other similar tasks. It is equipped with a long telescopic boom that may be moved forward, backward, or lifted and lowered at will.

Depending on the specific demands of the task at hand, a telescopic boom’s distal end may be fitted with a variety of different attachments, such as forklifts, buckets, cabins, lifting jibs, and so on.

Feller Bunchers

Source: Pinterest

The feller buncher is a piece of heavy equipment that is used in the construction industry for cutting down and removing huge trees. They cut the tree and grasp it without falling it, and then they collect all of the chopped-down trees in one location, which makes the task simpler for the loaders and dump trucks.

Dump Trucks

Source: Pinterest

On construction sites, vast volumes of material are transported from one construction site to another, as well as to the dump yard, using trucks equipped with dump beds. Off-road dump trucks are the standard vehicles used at large construction sites. Because these off-road dump trucks have massive wheels with an enormous capacity for materials, they can transport a significant amount of that material regardless of the terrain they are driving on.

known about the construction tools

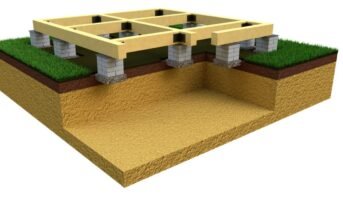

Pile Boring Equipment

Source: Pinterest

To install precast piles, machinery designed for pile drilling is used at the construction site to produce boreholes.

Pile Driving Equipment

Source: Pinterest

If pile foundations are being constructed, another kind of heavy equipment that may be encountered on the building site is pile-driving equipment. This piece of machinery lifts the pile, stabilises it so that it is in the correct position, and then drives it into the ground to the specified depth. Different varieties of pile driving equipment are provided notably, piling rigs, piling hammers, hammer guides etc. Hammering the pile top, which may either be done hydraulically or manually by dropping, is the method that is used to force the pile into the earth.

Excavators

Source: Pinterest

Excavators are essential pieces of equipment that are used extensively in the construction sector. Excavation is their primary function, but in addition to that, they may also be used for many other things, such as heavy lifting, demolishing structures, dredging rivers, cutting down trees, and many other things.

Both a long arm and a cabinet may be found in excavators. At the very end of the long arm that does the digging, there is a bucket given, and there is a cabinet provided for the operator of the machine. The fact that this whole cabin design can rotate up to 360 degrees makes the job much simpler. Wheeled and tracked versions of the vehicle that is known as an excavator are both on the market.

Backhoe

Source: Pinterest

The backhoe is another kind of versatile equipment that sees widespread usage and may be used for a variety of jobs. The name of the vehicle gives away the fact that the hoe arrangement is situated on the rear of the vehicle, while the loading bucket is situated on the front of the vehicle. This is quite helpful for digging trenches below the level of the machine, and it enables the loading, unloading, and lifting of items to be performed using the front bucket.

Dragline Excavator

Source: Pinterest

The dragline excavator is another kind of heavy equipment that is employed in the construction industry. Its primary function is to do excavations of greater depth. It is made out of a long-length boom, and the digging bucket is cable-suspended from the very top of the boom. The use of a dragline excavator is possible in various contexts, including the building of ports, excavations underwater, the removal of silt from water bodies, and more.

Bulldozers

Source: Pinterest

The removal of the topsoil layer to a certain depth may also be accomplished with the help of bulldozers, which are a form of soil-digging equipment. The sharp edges of the large metal plate that is given at the front of the device are what remove the dirt. Utilising hydraulic pistons, this plate’s height may be adjusted up and down. These are employed extensively in a variety of applications, including the removal of fragile soil or rock layers, the lifting of soil, and other similar tasks.

Graders

Source: Pinterest

Graders, also known as motor graders, are another form of construction equipment that are employed in the building industry, particularly in the construction of highways. Its primary purpose is to even out the surface of the soil. It has a horizontal blade in the middle of the vehicle, in between the front and back wheels, and when it is operating, this blade is lowered into the ground.

On top of the rear axle, an arrangement is where the cabin for operating the vehicle is located. Motor Graders may also be used for the removal of snow or dirt from roadways, the levelling of the soil surface before the application of an asphalt layer, the removal of an unwanted soil layer from the ground, and other similar tasks.

Wheel Tractor Scrapers

Source: Pinterest

Wheel Tractor Scrapers are pieces of earth-moving equipment that are used to scrape the surface of the soil to level it out. The front section houses the wheeled tractor vehicle, while the back section houses the scrapping system, which may include a horizontal front blade, a conveyor belt, and a dirt-collecting hopper.

When the front blade is dropped onto the ground, and the vehicle is pushed, the blade will start digging the soil that is above the blade level, and the dirt that is dug up will be collected in a hopper through a conveyor belt. When the hopper is ready to be unloaded at the soil dump yard, the back portion is lifted off the ground, and the hopper is dumped there.

Trenchers

Source: Pinterest

Trenchers and other types of trenching devices are used in the process of excavating trenches in the ground. Trenches like this are often dug for a variety of reasons, including the installation of pipelines and cables, drainage systems, etc. Chain trenchers and wheeled trenchers are the two primary varieties of trenching devices that are commercially available.

Trenchers that use chains have a long arm that is fixed in place and around which a digging chain is placed. Trenchers on wheels typically have a metal wheel that has digging teeth wrapped around it. Wheeled trenchers are the most effective tools to use while excavating layers of hard soil. Both kinds of trenchers may be purchased as wheeled or tracked vehicles, depending on the user’s preference.

Loaders

Source: Pinterest

On a construction site, loaders are used to load material into dumpers, trucks, and other vehicles. The materials might be raw resources, excavated soil, debris from demolition, or any number of other things. The front bucket of a loader is often rather big, while the moving arm is typically quite short.

Loaders may either have tracked or wheeled propulsion. On construction sites, wheeled loaders are the most common loader, while tracked or crawling loaders are often utilised in areas that wheeled vehicles cannot access.

Tower Cranes

Source: Pinterest

Tower cranes are a specific kind of stationary crane that is used for lifting purposes in the building of tall constructions. Using this kind of apparatus, even cumbersome things like pre-stressed concrete blocks, steel trusses, and frames, amongst other things, may be hoisted to the desired height with relative ease.

They are made up of a mast, which is the vertical supporting tower, a jib, which is the operational arm of the crane, a counter jib, which is the opposing arm, and an operator cabin, which is where the crane may be controlled from.

Paver

Source: Pinterest

Paving equipment, often known as an asphalt paver or just a paver, is essential to the building of roads. Paver is equipped with a feeding bucket that receives asphalt from a dump truck continuously.

Paver then spreads the asphalt in an equal layer on the road surface while applying a mild level of compaction. However, when the asphalt layer has been laid down, proper compaction can only be achieved with the use of a roller.

Compactors

Source: Pinterest

To compact the material or the earth’s surface, compactors and rollers are used. There are many various kinds of compactors available, and each one is designed to fulfil a particular kind of compacting need.

Rollers with smooth wheels are used for purposes such as compacting superficial layers of asphalt, earth, or other materials. When deep compaction is needed, sheep-foot rollers are the tool of choice. For compacting fine-grained soils, asphalt layers, and other materials, pneumatic tyred rollers are an effective tool.

Things to consider for effective construction equipment management

The management of construction equipment can be undertaken on a project-by-project basis or on an enterprise-wide scale. One of the most important considerations in the management of construction equipment is how cost-effective it is. The following are some of the factors that should be addressed for the efficient management of construction equipment.

- The selection of various pieces of construction equipment, as well as the quantity of each piece of equipment that is needed for a certain project.

- Determine if it is more cost-effective to own, lease, or rent the equipment, as well as how each option would affect the income statement and the balance sheet.

- The process of determining which pieces of machinery will be operating at which construction site, at what time, and for how long.

- When working with several projects and their respective timelines, it is important to take into consideration the expenses of transportation and operations.

- One should consider how to get the most out of the available building tools and construction equipment.

- Preventive maintenance of construction equipment is another essential component of efficient construction equipment management. This kind of maintenance may help save a significant amount of downtime, as well as money and decrease the risk of delays in the project.

The solution to making construction projects more cost-efficient while also guaranteeing that they are finished on schedule is, all things considered, to invest in highly effective construction equipment.

FAQs

What role does construction equipment play?

Utilising construction equipment effectively contributes to the project's economics, quality, safety, speed, and timely completion. It maximises the use of material, personnel, finances, and the scarcity of trained and efficient labour, while simultaneously maintaining a direct check on the employed quality standards.

Which piece of construction equipment is used the most often?

Construction sites often include a wide variety of different kinds of heavy machinery, and the most used construction equipment on a day-to-day basis are excavators, bulldozers, loaders, cranes, and dump trucks, to name a few.

What is construction equipment management?

Effective construction equipment management is the practice of regularly reviewing the effectiveness and efficiency of a company's construction equipment fleet, as well as the associated expenses. The review of a company's fleet and its fit with the company's present projects are also part of construction equipment management.

What is the planning for construction equipment?

Construction equipment planning involves identifying construction equipment for performing project activities, evaluating equipment performance capabilities, predicting the quantity and kind of equipment required by date, and then participating in the selection of equipment to be obtained.

What are the duties of a construction manager?

Managers of construction equipment are responsible for the maintenance and upkeep of a construction firm's machinery. They are the ones that have to pay for the tools, take care of any necessary repairs, and keep everything organised and ready for use at all times.

Housing News Desk is the news desk of leading online real estate portal, Housing.com. Housing News Desk focuses on a variety of topics such as real estate laws, taxes, current news, property trends, home loans, rentals, décor, green homes, home improvement, etc. The main objective of the news desk, is to cover the real estate sector from the perspective of providing information that is useful to the end-user.

Facebook: https://www.facebook.com/housing.com/

Twitter: https://twitter.com/Housing

Email: [email protected]