A tower crane is essential for constructing skyscrapers, other large buildings, and intricate endeavours. This apparatus is designed to guide and direct heavy machinery at elevated work sites. Creating a tower crane for optimal performance and safety is no easy task. Often, a foundation is used to secure the crane within the building site.

The apparatus consists of a vertical metal rig that holds up a horizontal lever, arm, canvas, or jib. The horizontal lever can be turned through a complete circle. Cranes have steadily increased in size and strength throughout construction history to aid construction workers in their quest for increased productivity, speed, and safety. Cranes can be either stationary or mobile, depending on the requirements of the job at hand.

The name “fixed crane” comes from the fact that these machines stay put for the project’s life and are disassembled before being moved. Overhead and tower cranes are two examples of popular types of fixed cranes. A tower crane, gantry crane, or jib crane is an inverted L-shaped crane that can raise many tonnes of weight to extreme heights.

See also: What is mobile crane?

Tower crane: History

The first tower cranes ever built were Derrick tower cranes. Thomas Derrick gave his name to these lifting devices, which consisted of a boom coupled to a rotating base through a hinge. The ability to rent tower crane machinery did not exist in those days. In those times, the construction team had to think of an imaginative way to lift heavy objects.

Tower crane: Importance

Modern tower cranes improve the productivity and timeliness of construction firms. These workhorse necessities allow you to breeze through even the most challenging jobs. Think of a massive building site that doesn’t have any tower cranes. Nobody on the construction crew could carry the heavy energy generator up the building’s several flights of stairs.

Tower crane: Benefits

Using tower cranes makes even the most challenging tasks manageable for construction project managers. The tasks typically assigned to them include:

- Moving heavy equipment.

- Concreting a portion of the construction.

- Carrying building supplies.

- Lifting and putting steel beams.

Such things are vitally necessary for building sites and the construction sector to have in place.

With tower cranes, construction of tall buildings using more eco-friendly ways is possible even in the densest urban areas. In addition, they can complete building projects more quickly, effectively, and cheaply. The most appealing advantage of hiring a tower crane is the money saved on labour.

Tower crane: Types

The various forms of tower cranes can be categorised as follows:

Hammerhead crane

The jib of a hammerhead crane extends horizontally and is connected to a tower set upright. In the office, the jib stretches horizontally and is balanced by weights at one end. Transporting equipment is facilitated by a trolley holding the lift rope that slides along the jib. The cabin where the operator sits is where the jib and tower meet. A second tower crane is usually needed for setting up and breaking down this crane model.

Source: Pinterest

Self-erecting tower cranes

There is no need for a second crane to help install a self-erecting or self-assembling crane on site. This benefit is crucial in minimising the time to launch and the project’s overall cost. Even though the jib of some versions of this crane can be converted into an operator’s cabin, most self-erecting cranes are operated from the ground via radio or television. The towers of this sort are often self-sufficient and mobile, allowing them to be relocated as needed.

Source: Pinterest

Luffing jib tower crane

Urban areas are typically too crowded to allow for jib rotation. Most tower cranes have a horizontal jib that cannot be moved, but a luffing jib can be raised or lowered to decrease the crane’s turning radius. When lifting passengers closer to the tower, a luffing jib can be used instead of an electric wagon because it can be raised and lowered as needed. Because of its high cost and intricacy, luffing cranes are only utilised in exceptional circumstances.

Source: Pinterest

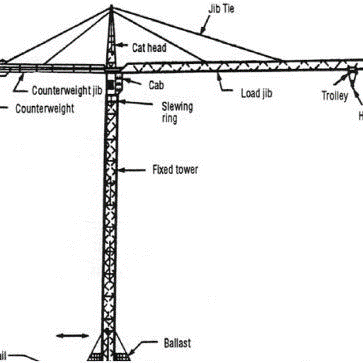

Tower crane: Components

Source: Pinterest

The following elements form its structure:

1. Base

It is the single most crucial component in keeping the crane upright. The concrete foundation is poured in advance of the crane installation process. This base serves as an anchor for the crane.

2. Mast

The mast is the set of truss-like columns that allow the crane to reach its desired height. They are not one solid column but pieces that can be easily bolted together to other parts of the crane. The crane is secure due to the concrete foundation and the mast columns.

3. Slewing unit

The crane can swing into different positions thanks to the slewing unit’s gear and motor set-up.

4. Working arm

It extends perpendicular to the mast and contains the hook and trolley to hoist the cargo.

5. Machinery arm

This structure, called a “counter jib,” is where the crane’s counterweights and balancing pulleys are kept.

6. Hook and trolley

The hook serves as the primary mechanism for supporting weight when transporting cargo. The hook may be moved towards and away from the mast on a trolley, and it can also be raised and lowered. The trolley is outfitted with several wires and pulleys to accomplish this.

7. Operator cab

The crane’s slewing unit is connected to its control centre. The operator must ascend ladders within the mast to reach the cab.

Principles behind tower crane operation

Tower cranes have very straightforward operating principles. Overturning forces are balanced by the concrete pad and counterweights suspended from the equipment arm. So, while a crane is empty, it is slightly unbalanced due to the counterweights, and it is when loads are being hauled, the crane is steady.

A winch connected to the trolley through steel cables pulls loads. The crane’s stability is affected by the distance at which the load is hauled from the mast, as this is where overturning forces are generated. Heavier loads are hoisted nearer the mast than lighter ones to reduce the resulting forces.

The crane has a maximum load restriction and a load-moment limit switch to prevent overloading. These switches monitor the ‘collapse’ and trigger an alarm if a predetermined value is reached.

How to choose the right tower crane for your project?

These key considerations play a pivotal role in ensuring the efficient and safe operation of a tower crane:

- Required Capacity: The choice of tower crane model or design should align with the specific lifting requirements of your project. Lighter models are suitable for tasks like hoisting formwork and concrete buckets, while heavier-duty cranes are essential for lifting substantial equipment such as generators and large steel components. It’s also essential to identify critical lifts, those within 10% of the crane’s total capacity, which may require special engineering considerations.

- Space Availability: The availability of space around your crane location is of paramount importance. Adequate clearance from surrounding structures and infrastructure is essential to ensure smooth crane operation. It’s crucial to prevent the crane from interfering with nearby buildings or critical infrastructure like overhead power lines. When siting the crane near sidewalks or public roadways, be prepared to implement safety measures, including overhead protection or special procedures, to protect the public. In situations involving multiple tower cranes on-site, carefully consider the swing radius of each crane to optimise their placement and avoid collisions.

- Pick Locations: Efficient crane operation is closely tied to the selection of pick locations. Tailor your crane placement to minimise the distance between the crane and loading docks, which are vital for material transportation on the construction site. Remember that the crane’s lifting capacity decreases as the load moves further from the mast.

- Flight Paths: For construction sites in proximity to airports, aviation authorities might impose specific regulations and permits due to concerns about aircraft encountering tower cranes. Make sure to consult with local aviation authorities to understand any necessary permits, operating restrictions, and height limitations before erecting the crane.

- Installation and Removal: The process of installing and later removing a tower crane can be logistically complex and may require substantial equipment. Consider these aspects when planning your crane location to avoid challenges during removal, which could potentially delay project completion. If multiple tower cranes are on-site, consider sequencing their removal and installation to facilitate a smoother process and expedite the completion of different areas of your building.

FAQs

What are the uses of a tower crane?

Tower cranes are needed to move heavy tools, materials, or goods around a construction site. They are great for speeding up construction, staying on schedule, and saving money on time and labour.

How much can a tower crane carry?

For bigger building projects, a fixed tower crane is used. These cranes can lift up to 300 metres high and have a maximum working radius of 70 metres.

| Got any questions or point of view on our article? We would love to hear from you. Write to our Editor-in-Chief Jhumur Ghosh at [email protected] |

Housing News Desk is the news desk of leading online real estate portal, Housing.com. Housing News Desk focuses on a variety of topics such as real estate laws, taxes, current news, property trends, home loans, rentals, décor, green homes, home improvement, etc. The main objective of the news desk, is to cover the real estate sector from the perspective of providing information that is useful to the end-user.

Facebook: https://www.facebook.com/housing.com/

Twitter: https://twitter.com/Housing

Email: [email protected]